MEGASIM: Simulation Consulting Services

Revolutionizing Engineering with Simulation Expertise

Welcome to MEGASIM Consulting Services, a distinguished division of the Megalab Group. At MEGASIM, we specialize in the fusion of test and simulation to deliver innovative solutions for complex engineering challenges.

Request a Quote

To provide you with an accurate quote, we need a little more information about your requirements. Please take a few moments to fill out the form below, and one of our experts will be in touch with you shortly.

Introducing MEGASIM Consulting Services

Welcome to MEGASIM Consulting Services, a distinguished division of the Megalab Group. At MEGASIM, we specialize in the fusion of test and simulation to deliver innovative solutions for complex engineering challenges.

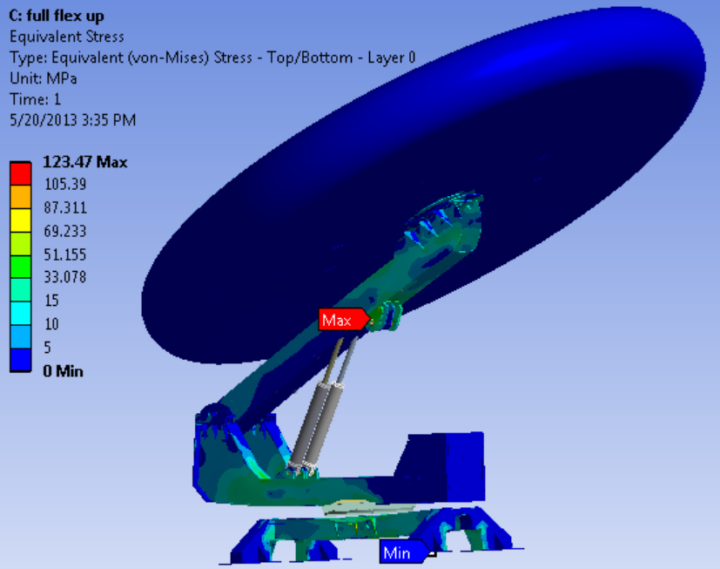

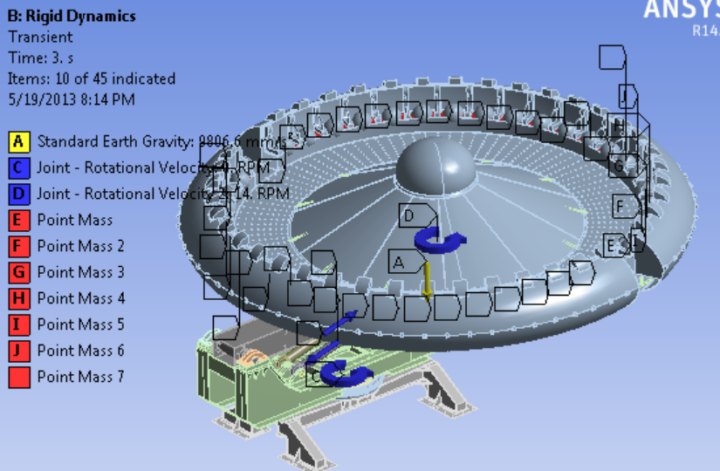

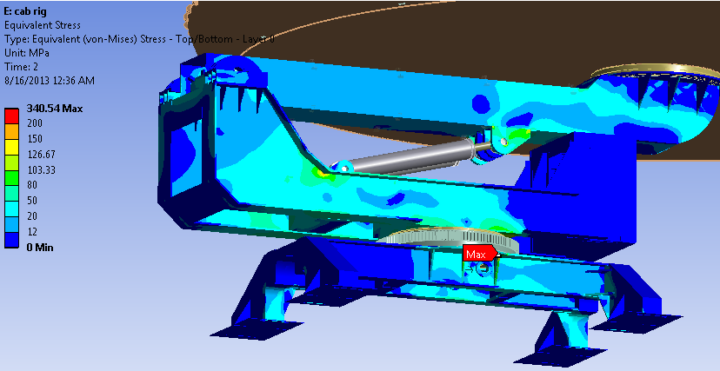

Advanced Simulation Expertise

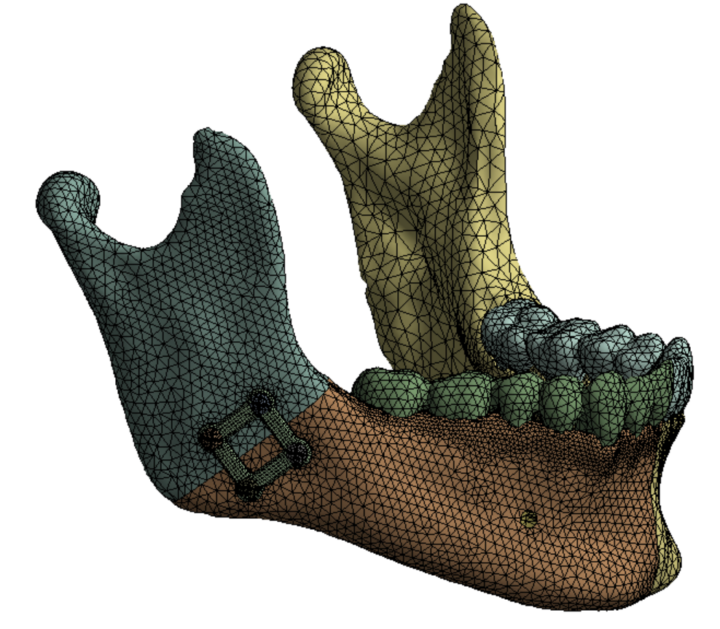

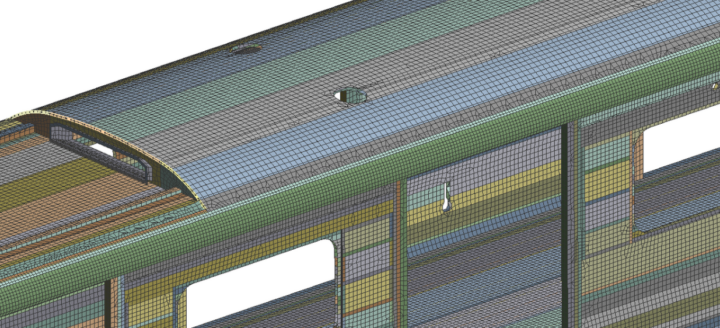

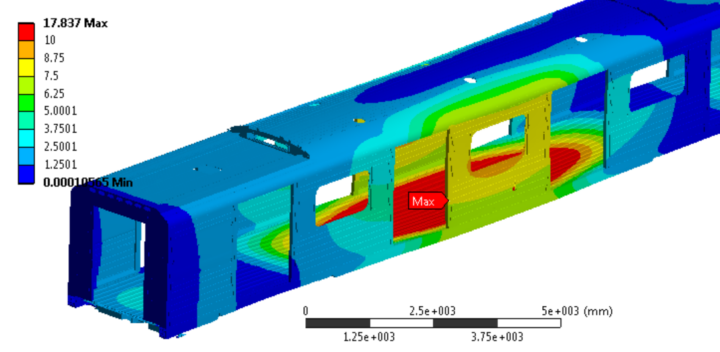

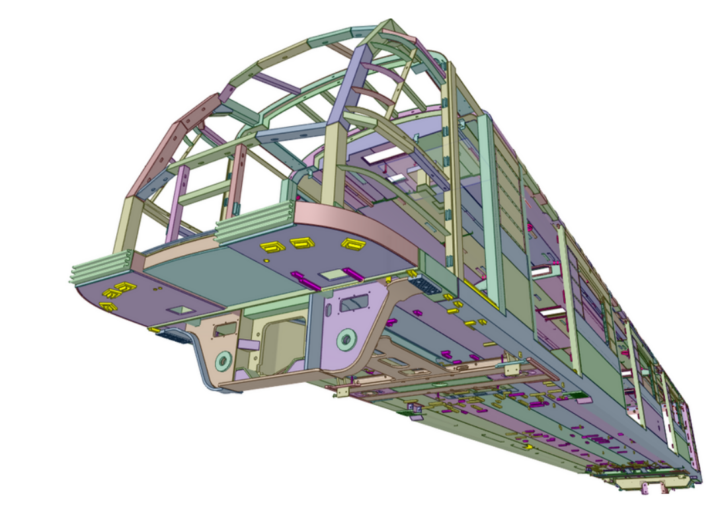

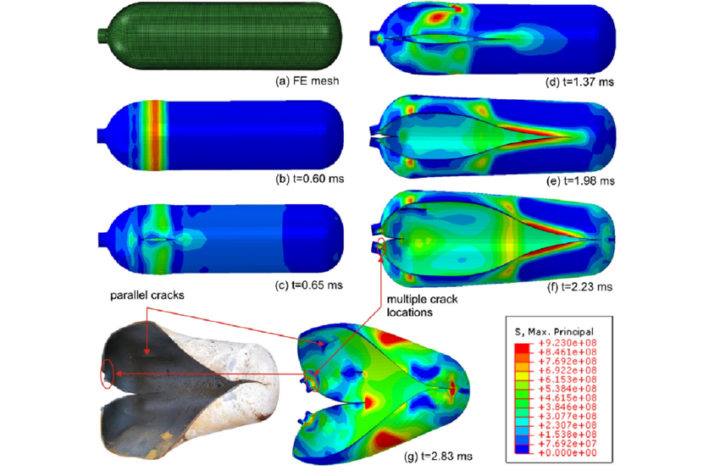

Our dedicated and knowledgeable team at MEGASIM harnesses cutting-edge computer simulation technologies to provide comprehensive solutions tailored to your needs. Leveraging state-of-the-art software, we offer a range of analyses including structural (linear and non-linear, static, fatigue), fluid mechanics, and thermal/thermo-mechanical analysis. With years of experience and access to high-capacity computing resources, our skilled staff delivers precise results efficiently.

Trusted Partners in Decision-Making

Establishing the credibility of simulation models is crucial for making informed decisions in design and certification processes. MEGASIM serves as your trusted partner, enabling faster and safer innovation for our clients.

Your Path to Success

At MEGASIM, we are committed to guiding you through engineering challenges with precision and efficiency. Collaborate with our consultants to unlock innovative solutions and optimize your product development process.

Contact Us Today

Discover how MEGASIM can elevate your engineering projects to new heights. Reach out to us for a consultation and experience the power of fusion between test and simulation.

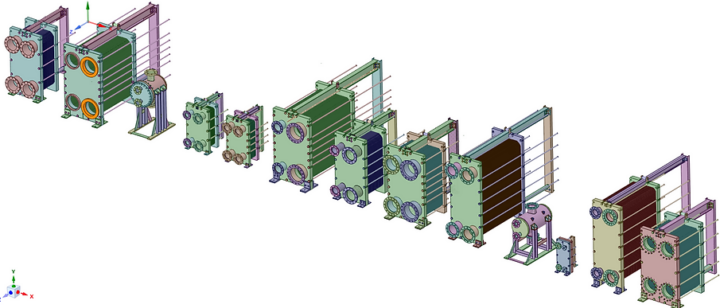

Key Services Offered

Our consulting services encompass a broad spectrum of engineering disciplines. Partner with us to benefit from our expertise in:

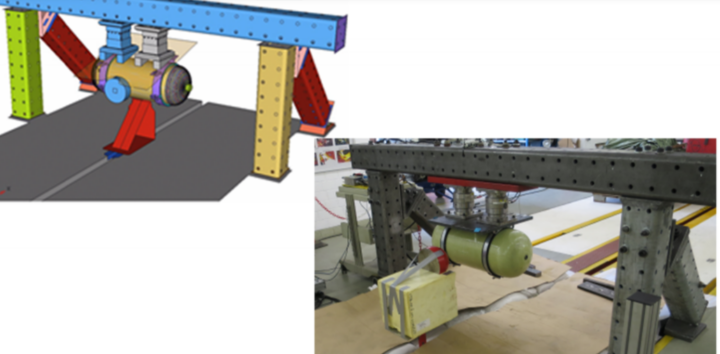

- Shock, Vibration, and NVH Analysis

- Seismic Analysis

- Drop simulation

- Nail Penetration analysis

- Crush and Impact simulation

- Fatigue, Fracture Mechanics, and Durability Analysis

- Design Optimization

- Incident Analysis, Investigation, and Site Validation

- Fluid Dynamics and Thermal Analysis

- Particle and Pollution Distribution Analysis

- Optimizing Combustion Processes

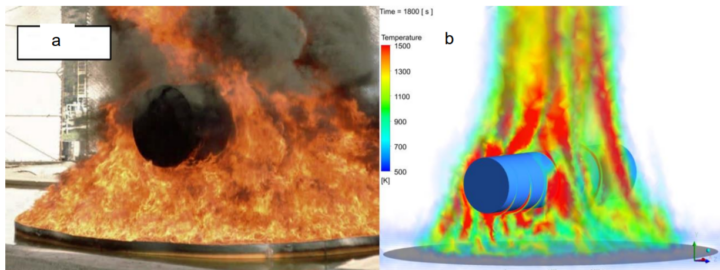

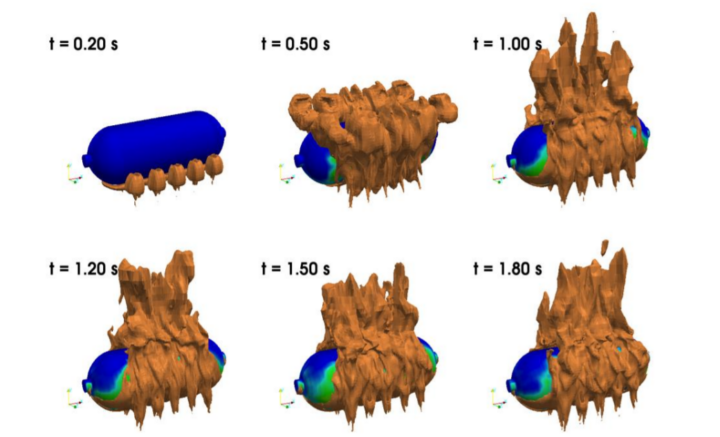

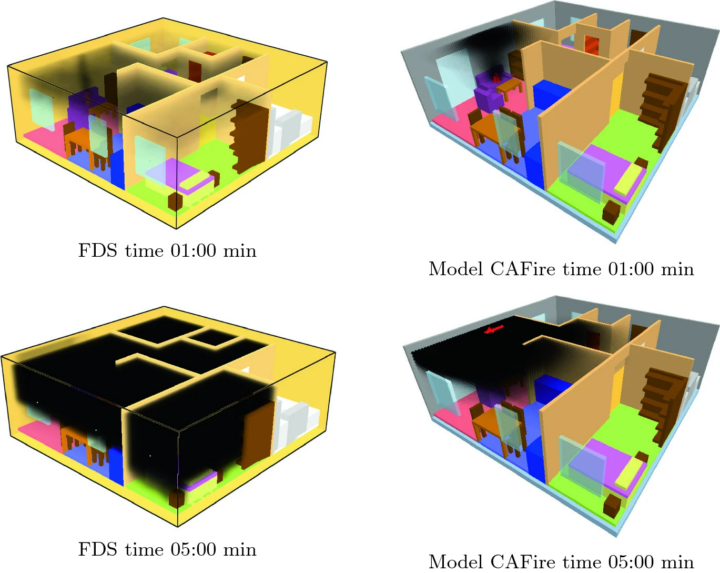

- Fire, Explosion and Smoke Propagation Modelling – Pollutant Dispersion

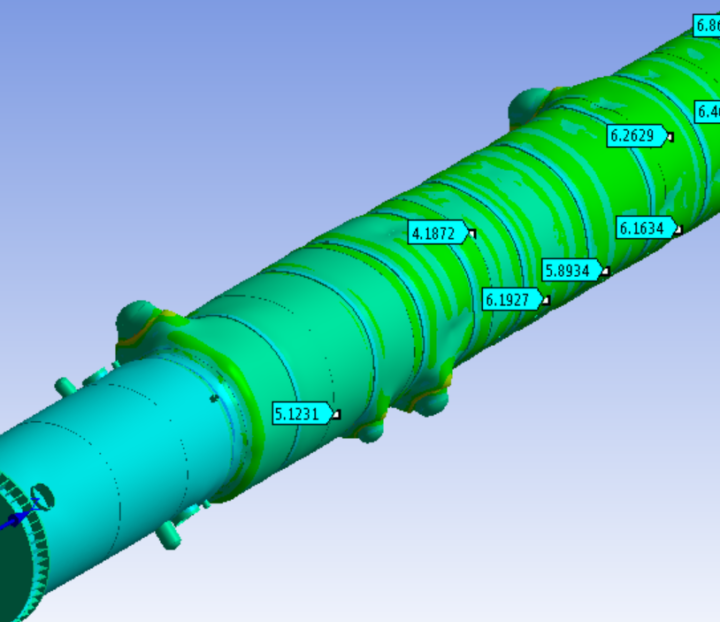

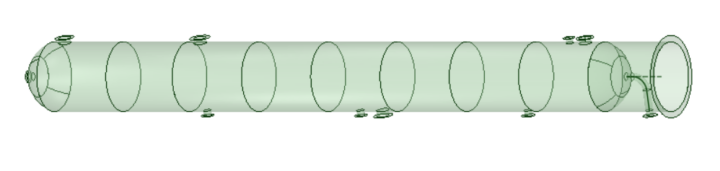

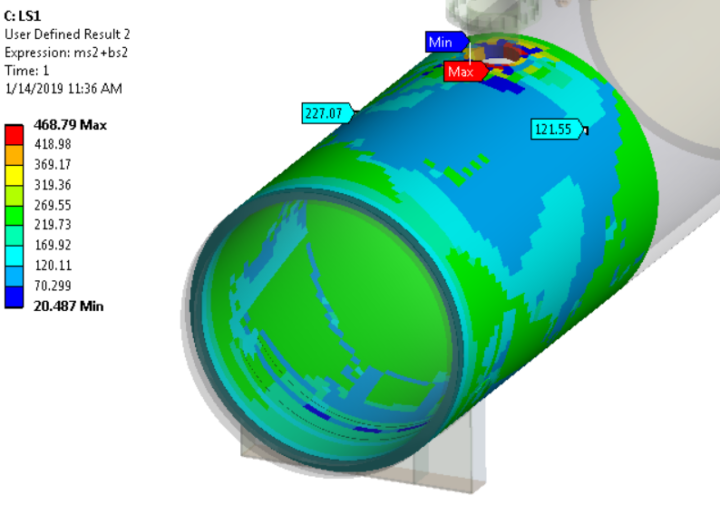

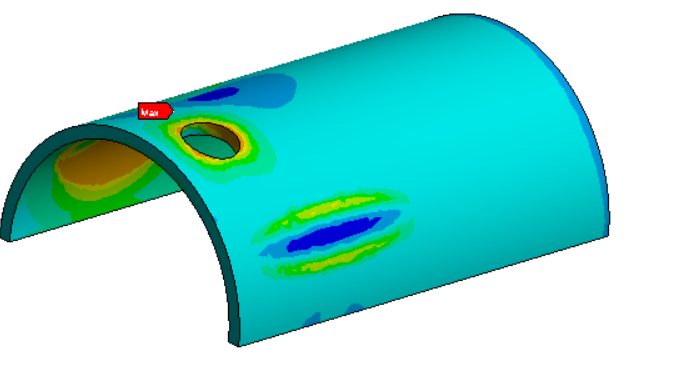

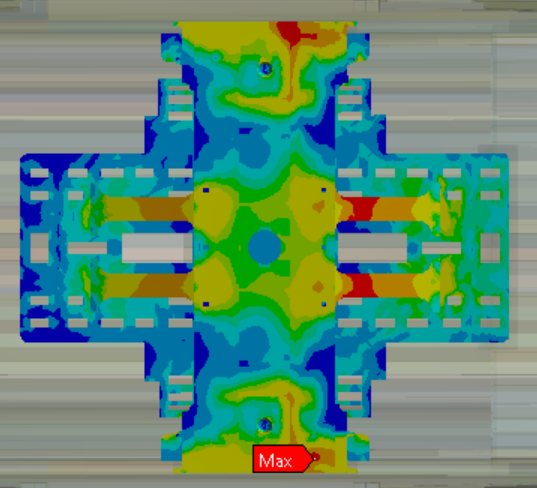

Sample Project

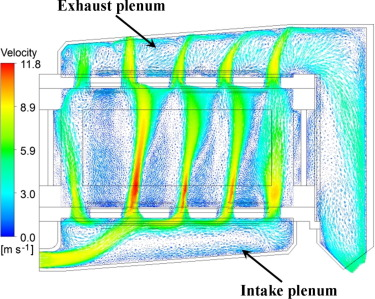

Computational fluid dynamic and thermal analysis of Lithium-ion battery pack with air cooling

Purpose: Thermal performance of the battery pack when the battery pack is large and full transient simulation is not viable

Challenges: In order to show the accuracy of the measurements, a thorough uncertainty analysis was performed